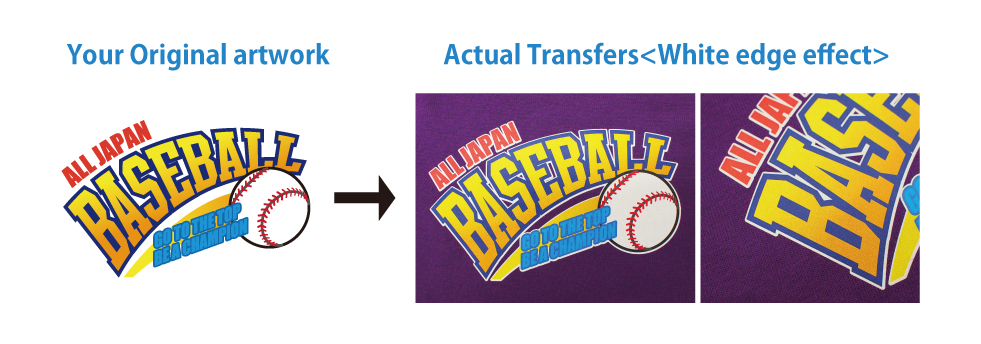

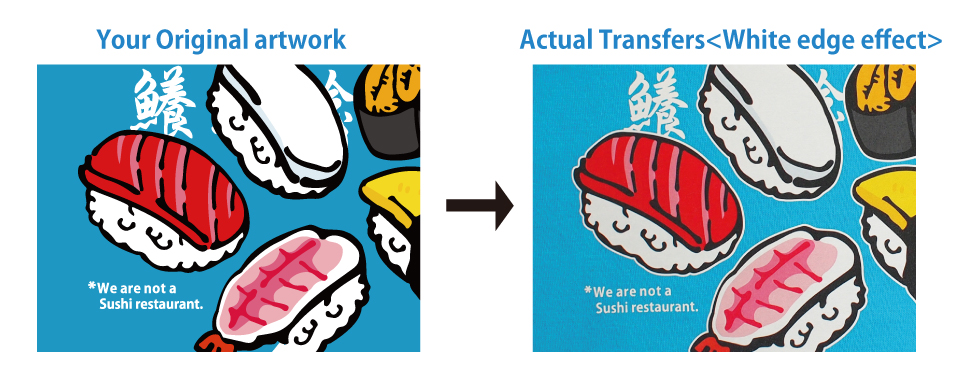

This is the most popular type among OZAKI’s Gang Transfers. Full color and detailed image can be precisely expressed by the manufacturing method for our digital transfers. White edge is placed around the artwork, and this type is recommended especially for emblem and logo designs because your designs turn to look more dynamic with white edge.

Descriptions

Product Type

Custom Digital Heat Transfers in full color

Advantages

Capable of Multi-color in small quantity. Economical price. Precise imaging.

Material

Urethane resin with water color pigment

Usage

Dark and Light colored fabrics

Cotton / Cotton & Poly / Polyester

Base of Sheets

Paper or Clear film

![]() Transfers with clear film base is more soft feel, and easier for positioning labels on garments.

Transfers with clear film base is more soft feel, and easier for positioning labels on garments.

Color

Full Color (except gold, silver and fluorescent colors)

Graphic Edge

White

Note. NO white edge around WHITE lines and letters.

White letters in your artwork are processed as they are provided.

Maximum size of graphic

15.74”×11.0”

Minimum order quantity

10 sheets

Peel

Cold

Packaging

50 sheets per bag

Quality

Passed on public quality examination

Lead Time

3-4 business days

Pricing

| Fine Paper Base / Per Sheet Price (USD) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Qty. | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 200 | 300 | 400 | 500 | 1,000 |

| $17.94 | $11.26 | $7.33 | $6.21 | $5.18 | $4.61 | $4.20 | $3.91 | $3.56 | $3.41 | $2.80 | $2.66 | $2.58 | $2.53 | $2.43 | |

| Fine Film Base / Per Sheet Price (USD) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Qty. | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 200 | 300 | 400 | 500 | 1,000 |

| $18.32 | $11.71 | $8.84 | $7.51 | $6.44 | $5.98 | $5.46 | $5.16 | $4.78 | $4.63 | $4.00 | $3.86 | $3.75 | $3.71 | $3.61 | |

![]() Above 1,000sheets, ask for quote.

Above 1,000sheets, ask for quote.

Prices are subject to change without notice.

Artwork Submission Guideline

Applications

![]() Adobe Illustrator CS5 or older

Adobe Illustrator CS5 or older

Format: ai., eps., pdf.

Color mode: CMYK

Font: Convert all font to OUTLINE

![]() Adobe Photoshop CS5 or older

Adobe Photoshop CS5 or older

Format: psd., jpg., eps. pdf.

Resolution: 200 dpi at the actual print size

Color mode: CMYK

* No color background (if necessary, make a separate background layer.)

* To achieve the best quality output printing, provide 200 dpi data. Lower resolution data can be used, but it

might be rough finishing.

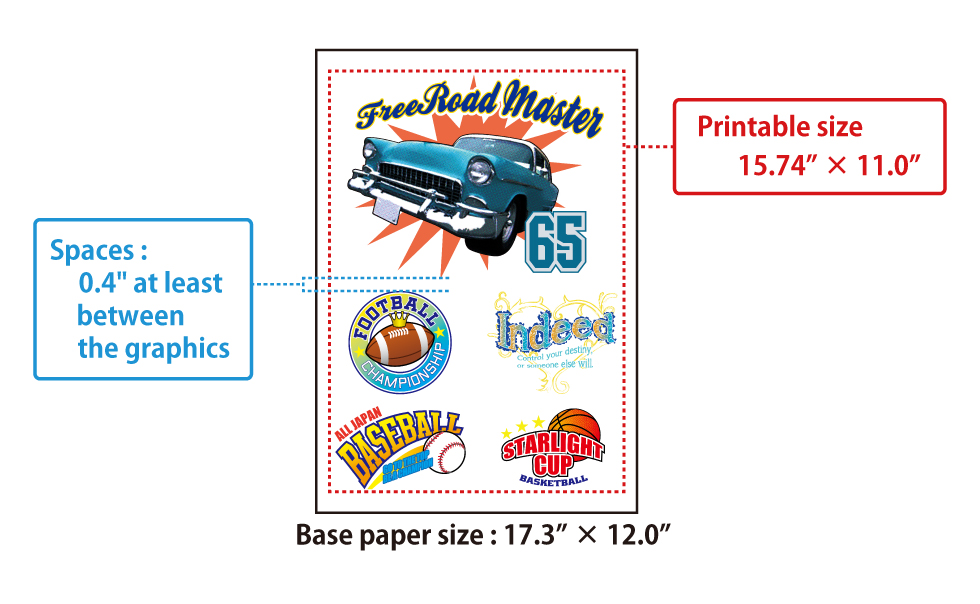

Printable Size

15.74”×11.0”

Spaces

Leave 0.4” spaces between the graphics

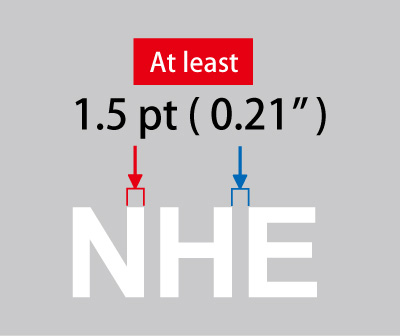

Line Width

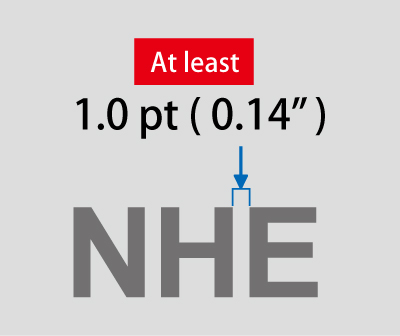

at least 1point or 0.14” for WHITE lines and letters. No limit for other colors.

If white lines are thinner than 1 point or 0.14”, they can not be clearly represented.

![]() White lines and letters are processed as they are provided.

White lines and letters are processed as they are provided.

Opening Area Width

at least 1point or 0.14” between WHITE lines. No limit for other colors.

![]() If areas between white lines are thinner than 1 point or 0.14”, opening area can not be kept but they might be

If areas between white lines are thinner than 1 point or 0.14”, opening area can not be kept but they might be

painted in white.

Submit

Send your artwork at actual size that is laid out within printable size. Upload from Upload page.

Color Instruction

Make sure that color mode be CMYK.

Areas you want to print white in your artwork, use white. Where there is no color in your artwork will be no ink. (will be garment color)

![]() Please note that colors of actual transfers cannot be exactly the same to colors shown on you monitor or output

Please note that colors of actual transfers cannot be exactly the same to colors shown on you monitor or output

from your printer. This is due to the process of digital printing and environmental difference in computers,

monitors or printers. Characteristic of ink and any conditions added to transfers during the production process

canalso make difference in colors.

Graphic Edge

Graphic edge will be white, which will be as thick as about 2 points or 0.28”.

You do not need to create white outline when submitting your artwork. We will do it and let you approve it with proof file.

However, if you wish thicker white edge or specific shaped white edge, please create position indicating line.

Note: If your artwork is Photoshop data, please create position indicating line in a different layer.

Proof

To prevent misprocessing your artwork due to garbled data, save your artwork file as jpg. or pdf. and send it to us with your artwork in original format. We will create finishing image saved as jpg, and send it back to you.

Layout Samples

Press Instruction

Press machine

Clamp-shell type transfer press machine

Temperature

284F~302F (140℃~150℃)

Time

10 seconds

Pressure

Mid to High pressure 36~50 PSI (Adjust depending on the material)

* After completely cool off, remove the base paper.

![]() The press machine setting (temp., pressure and press time) may vary depending on the type of the machine

The press machine setting (temp., pressure and press time) may vary depending on the type of the machine

which you use.

We strongly recommend to test-press to adjust the setting.

HIX Corporation www.hixcorp.com

Recommended Point

Our digital transfers differ from plotter cut transfers that are difficult to make a detailed shape.

Fine is able to represent small characters and lines.

|

|